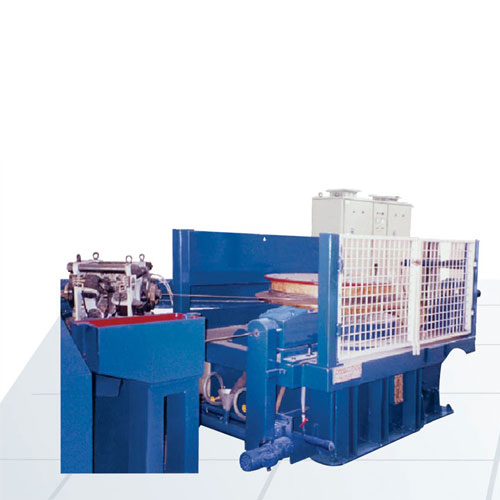

Wire Drawing Machines

ASSOMAC offers high-speed integrated Cold Ribbed Wire Lines for continuous drawing and ribbing of Mild Steel low Carbon Wire Rods and Stainless Steel Wire Rods used for construction bars & mesh welding.

ASSOAMC was entrusted by its honoured customers with the responsibility of providing a modern, high-speed, simple-to-operate, low cost and low-downtime machine. So we went to the drawing board and came up with several offerings to suit our customer needs. This line consists of a double sken type tilting Pay Off which is a hydraulically operated wand that has entanglement sensors for non-stop high-speed wire rod payoff. There is an inline Descaler in the horizontal and vertical plane with a motorized brushing arrangement and motorized wire pre lubricating unit. Then there is a Double Deck Drawing-cum-Ribbing Machine with or without a two-speed gearbox. The lower deck is for sizing and the upper deck is for ribbing. The line consists of an imported Ribbing Cassette which has options for different ribbing patterns, cheese type spooler with hydraulically operated traverse, spool clamping, spool lifting and spool shifting for fast and easy loading/unloading of Spools. Also Collapsible Spools, Butt Welding Machine, variable speed A.C. Vector Frequency Drive Control Panel and operator control station are P., of the complete plant.

Silent Features :

- Standard European Ribbing Cassette used.

- Hydraulically tiltable dual head payoff for continuous easy feeding of wire rod coils by overhead crane or fork lift.

- Hydraulically bitable neck type overhead pulley for faster-slinging operation and easy operator reach.

- Dual plane adjustable roller descaler with hardened wear-resistant rollers with long service life with inline motorized brushing unit for absolute scale-free rod surface.

- Motorized lube box for better lubricant coating before pre-drawing.

- Double Deck Chromium Carbide Matrix-Coated Capstans are internally water-cooled for long service life.

- Suitable operator safety features built—in the system like guards, wire break sensors, safety locks, emergency brakes etc.

- Pneumatic/Hydraulic clamping, shifting, lifting and setting of spools for faster working atthe spooler.

- The complete plant is controlled by one operator from the control desk and has a well.programmed production process.

- Traverse with heavy-duty hydraulic cylinders with hardened guide rods individually motorized belt-driven pneumatic clamping traverse.

Technical Data :

| Intel Wire Rod Dia | 1.4 - 5.5 mm |

| Finish Wire Dia | 1.2 - 4.0 mm (Ribbed / Plain) |

| No. of Dies | 1 Pre Rolling Cassette + 1 Ribbing Cassette |

| Line Speed* | 8 - 12 mtrs./sec.(*Model Dependent) |

| Power Requirement | 3 HP at Pay Off 8 HP at Descaling 220 HP at Drawing Cum Ribbing Block 40 HP at Ribbing Block 40 HP at Spooling Spooling 3 HP at Spooler Power Pack |

| Brakes | Through Dynamic Breaking & Pneumatic Breaks |

| Transmission | Through Heavy Duty Gear |

| Controls | Synchronized A.C. Variable Frequency Drives Speed Reduction gear Box |